The SCOR Model is a reference process model, developed by Supply Chain Council. This model is widely used across industries. It helps businesses better understand business processes, operational performance and goals. It also identifies areas for improvement and allows them to compare their performance with that of their peers.

The model is divided up into three major segments, namely process modeling and performance measurement. The first part of the model focuses primarily on planning, procurement, production and delivery. The model also covers market interactions and returns.

This segment of the model also provides more than 150 key performance indicators (KPIs) that you can use to measure the success of your operations. For example, you can evaluate the delivery performance of your suppliers and determine whether they are providing quality products at a reasonable cost.

You can also analyze customer returns to determine the savings you would achieve if suppliers reduced their return rates by 20%. You can identify areas in which you could save money by improving processes.

The SCOR model can be confusing to those who are unfamiliar with it. The main objective of the model is to create a standard, effective system for managing your supply chains.

It breaks the chain down into ideal business process, and divides these processes into categories depending on what they do for your organization. The system allows you to easily compare and coordinate supply chain activities both within your own company and across all industries.

The second segment of the model is performance measurements, which is made up of metrics that you can use to evaluate the overall success of your supply chain operations. These metrics are useful for evaluating a wide range of performance areas including inventory management and transportation costs. They can also be used to assess customer service, supplier quality, or even the overall success of your supply chain operations.

The data from the performance measurement can be used to determine how well your company performs in each of these areas, and then set up action items for improving your operations. It is important to note that these measures are only useful if you take the time to do something about them.

You will first need to create a list with current KPIs you can monitor. Then, you can start to review each of these metrics monthly to see how your company is doing in each area.

It's a great time to start thinking of new ways your company can implement business processes. This will help you improve operations and increase profits. Compare the new processes you have implemented with your existing ones to determine if they are effective.

This is an excellent way to get you and your team started in improving the supply chain operation of your company. In addition, the SCOR model provides an opportunity for companies to collaborate with their suppliers and customers by sharing a common language and framework for measuring and analyzing supply chain performance.

FAQ

How can efficiency in manufacturing be improved?

First, we need to identify which factors are most critical in affecting production times. Then we need to find ways to improve these factors. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you've identified them all, find solutions to each one.

What are the responsibilities of a logistic manager?

Logistics managers are responsible for ensuring that all goods arrive in perfect condition and on time. This is done using his/her knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

What are the products of logistics?

Logistics are the activities involved in moving goods from point A to point B.

They include all aspects of transport, including packaging, loading, transporting, unloading, storing, warehousing, inventory management, customer service, distribution, returns, and recycling.

Logisticians ensure that the product is delivered to the correct place, at the right time, and under safe conditions. Logisticians assist companies in managing their supply chains by providing information such as demand forecasts, stock levels and production schedules.

They also keep track of shipments in transit, monitor quality standards, perform inventories and order replenishment, coordinate with suppliers and vendors, and provide support services for sales and marketing.

Statistics

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

External Links

How To

How to Use lean manufacturing in the Production of Goods

Lean manufacturing is a management style that aims to increase efficiency and reduce waste through continuous improvement. It was developed in Japan during the 1970s and 1980s by Taiichi Ohno, who received the Toyota Production System (TPS) award from TPS founder Kanji Toyoda. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing can be described as a set or principles that are used to improve quality, speed and cost of products or services. It is about eliminating defects and waste from all stages of the value stream. Lean manufacturing is also known as just in time (JIT), zero defect total productive maintenance(TPM), and five-star (S). Lean manufacturing emphasizes reducing non-value-added activities like inspection, rework and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing is a great way to manage the entire value chain including customers, suppliers, distributors and retailers as well as employees. Many industries worldwide use lean manufacturing. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Five basic principles of Lean Manufacturing are included in lean manufacturing

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize & simplify - Make processes consistent and repeatable.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing, although not new, has seen renewed interest in the economic sector since 2008. Many businesses have adopted lean manufacturing techniques to help them become more competitive. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

With many benefits, lean manufacturing is becoming more common in the automotive industry. These include better customer satisfaction and lower inventory levels. They also result in lower operating costs.

You can apply Lean Manufacturing to virtually any aspect of your organization. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types in lean manufacturing

-

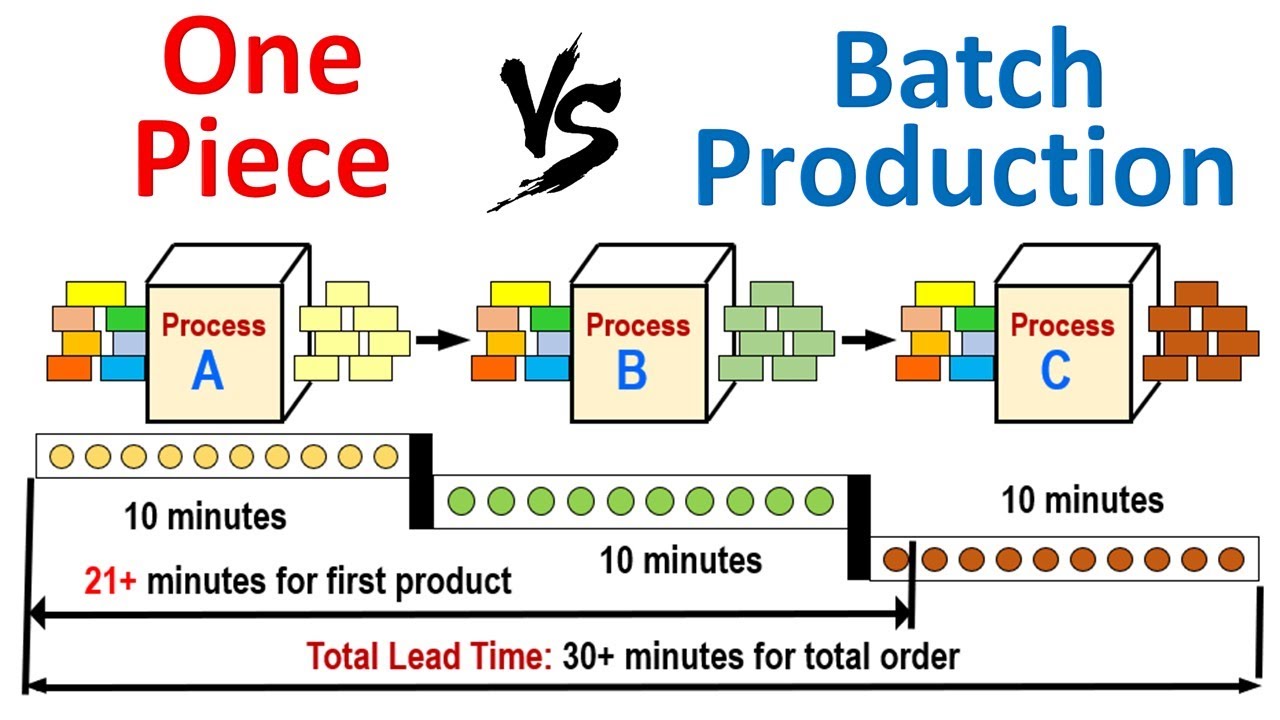

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This approach reduces lead time, increases availability and reduces inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This also applies to finished products that need minor repairs before being shipped.

-

Continuous Improvement (CI): CI aims to improve the efficiency of operations by continuously identifying problems and making changes in order to eliminate or minimize waste. Continuous improvement refers to continuous improvement of processes as well people and tools.