When looking at the economics of consumer goods, there are two categories: durable goods and non-durable goods. Durable goods are durable and last a long time. Non-durable products have a shorter lifecycle and need to be replaced more often.

Durable products, such as clothes and cars, are long-lasting and do not need to be replaced often. This makes durable goods more expensive, but they are also considered to be safer because they can't be worn out as easily or consumed as quickly as non-durables.

The distinction between durable and not-durable products is useful for both economists and investors, as it provides a quick and simple way to understand the economic situation. In an expanding economy, households and business are more likely purchase durable goods. However, during a slump, these purchases tend to be held back.

The durable goods index is a monthly economic report that gives an overview of the U.S. manufacturing industry and economy.

The increase in durable goods orders is an indication that the manufacturing industry expects to grow. Manufacturing companies are more likely to hire, and this can strengthen the economy. The durable goods report can also indicate that manufacturers don't have as much optimism about the future.

A durable good is a tangible product that doesn't quickly wear out, break down or rot. It is not replaced often, and can be used multiple times before it loses its usefulness.

Some examples of durable products include clothes, computers and furniture. You can buy them and use them many times before the goods start to degrade.

Investing in durable goods is important for the economy. They're a sign people and companies expect an improvement in the economy. This means they are willing to spend on products and service that will improve their lives.

They can also increase employment which will increase productivity over time and reduce costs. Durable goods are also more environmentally friendly than non-durables because they use less energy.

The durable orders report is an economic indicator which measures the domestic and international demand of durable goods produced in the U.S. It's published by the United States Census Bureau, and is used as an economic leading indicator.

Economists and investors use durable goods orders as an indicator of the health of the economy. When the durable goods orders report increases, it indicates that consumers are more interested in purchasing products and services that will last longer than three years.

If the durable goods order report declines, this indicates that consumers have less interest in buying products and services which will last for less than three-years.

The durable goods reports is a report which measures the monthly demand for durables goods. Durable goods are those items that can last over three years. The durable goods report is a key indicator of the economy because it provides a clear view of the state of the business and the outlook for the future.

FAQ

What are the four types of manufacturing?

Manufacturing refers the process of turning raw materials into useful products with machines and processes. Manufacturing involves many activities, including designing, building, testing and packaging, shipping, selling, service, and so on.

How can manufacturing avoid production bottlenecks

The key to avoiding bottlenecks in production is to keep all processes running smoothly throughout the entire production cycle, from the time you receive an order until the time when the product ships.

This includes both quality control and capacity planning.

The best way to do this is to use continuous improvement techniques such as Six Sigma.

Six Sigma can be used to improve the quality and decrease waste in all areas of your company.

It is focused on creating consistency and eliminating variation in your work.

What are my options for learning more about manufacturing

The best way to learn about manufacturing is through hands-on experience. However, if that's not possible, you can always read books or watch educational videos.

What is the responsibility of a logistics manager?

A logistics manager ensures that all goods are delivered on time and without damage. This is done by using his/her experience and knowledge of the company's products. He/she also needs to ensure adequate stock to meet demand.

What is the difference between Production Planning, Scheduling and Production Planning?

Production Planning (PP), is the process of deciding what production needs to take place at any given time. This can be done by forecasting demand and identifying production capabilities.

Scheduling refers the process by which tasks are assigned dates so that they can all be completed within the given timeframe.

How can manufacturing efficiency be improved?

First, identify the factors that affect production time. Then we need to find ways to improve these factors. If you don’t know where to begin, consider which factors have the largest impact on production times. Once you have identified the factors, then try to find solutions.

Statistics

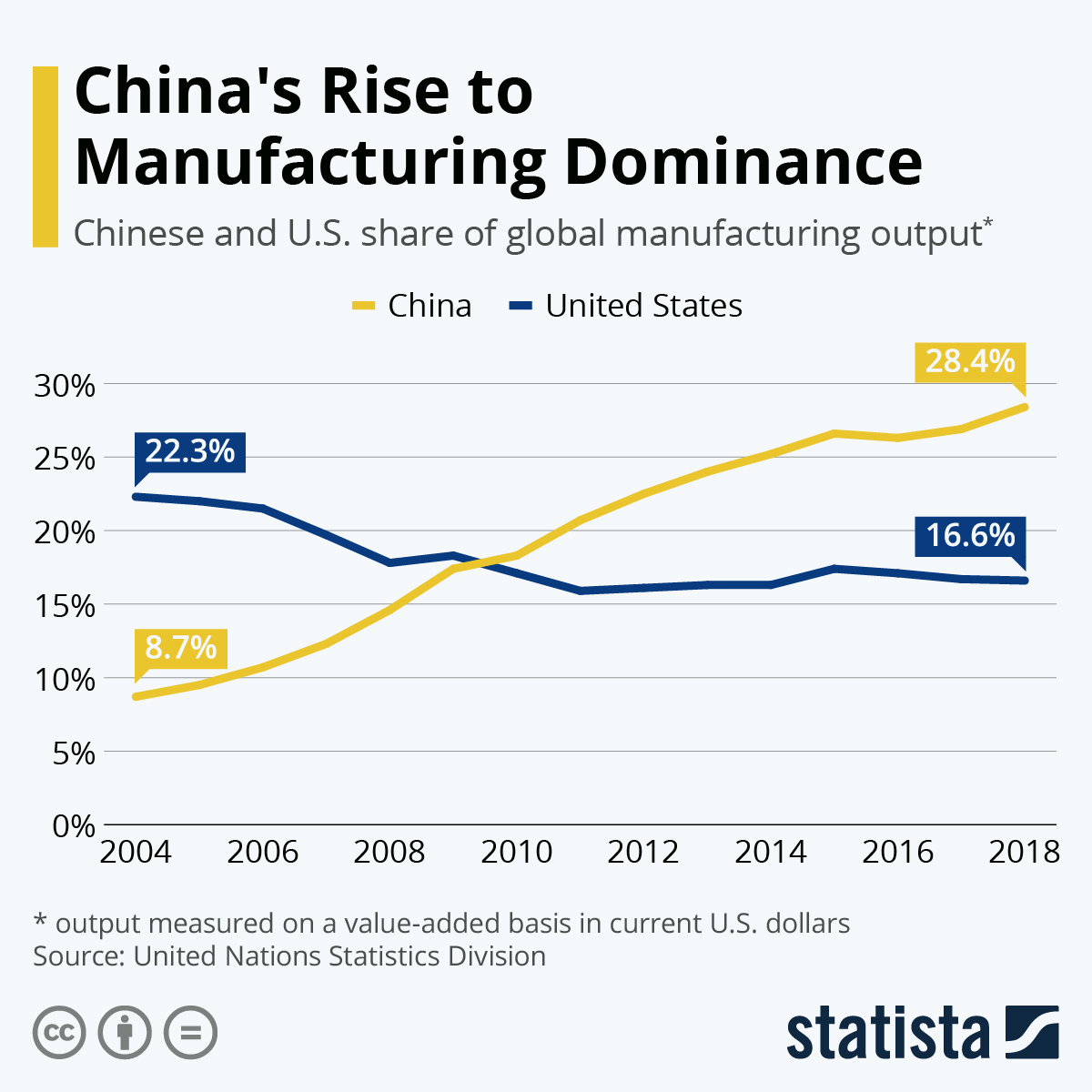

- [54][55] These are the top 50 countries by the total value of manufacturing output in US dollars for its noted year according to World Bank.[56] (en.wikipedia.org)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Many factories witnessed a 30% increase in output due to the shift to electric motors. (en.wikipedia.org)

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

External Links

How To

How to use lean manufacturing in the production of goods

Lean manufacturing is a management system that aims at increasing efficiency and reducing waste. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the book "The Machine That Changed the World", which was the first to be published about lean manufacturing.

Lean manufacturing is often defined as a set of principles used to improve the quality, speed, and cost of products and services. It emphasizes the elimination and minimization of waste in the value stream. Lean manufacturing is called just-in-time (JIT), zero defect, total productive maintenance (TPM), or 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing is a way for companies to achieve their goals faster, improve product quality, and lower costs. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing can be found in many industries. For example, Toyota's philosophy underpins its success in automobiles, electronics, appliances, healthcare, chemical engineering, aerospace, paper, food, etc.

Lean manufacturing is based on five principles:

-

Define Value: Identify the social value of your business and what sets you apart.

-

Reduce Waste - Remove any activity which doesn't add value to your supply chain.

-

Create Flow: Ensure that the work process flows without interruptions.

-

Standardize & Simplify - Make processes as consistent and repeatable as possible.

-

Build Relationships - Establish personal relationships with both internal and external stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses have adopted lean production techniques to make them more competitive. Economists think that lean manufacturing is a crucial factor in economic recovery.

Lean manufacturing is now becoming a common practice in the automotive industry, with many benefits. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Any aspect of an enterprise can benefit from Lean manufacturing. It is especially useful for the production aspect of an organization, as it ensures that every step in the value chain is efficient and effective.

There are three main types in lean manufacturing

-

Just-in-Time Manufacturing (JIT): This type of lean manufacturing is commonly referred to as "pull systems." JIT means that components are assembled at the time of use and not manufactured in advance. This strategy aims to decrease lead times, increase availability of parts and reduce inventory.

-

Zero Defects Manufacturing (ZDM),: ZDM is a system that ensures no defective units are left the manufacturing facility. If a part is required to be repaired on the assembly line, it should not be scrapped. This applies to finished products, which may need minor repairs before they are shipped.

-

Continuous Improvement (CI),: Continuous improvement aims improve the efficiency and effectiveness of operations by continuously identifying issues and making changes to reduce waste. Continuous Improvement (CI) involves continuous improvement in processes, people, tools, and infrastructure.