You can use your creativity to improve the world. Your work can make a huge difference in the lives of people, whether it's designing bridges or medical equipment, or cleaning up toxic waste.

It's important to choose a course that suits your interests and abilities. Kingston University offers undergraduate degree programs in engineering including chemical, electrical, civil, and mechanical engineering.

The first step in becoming a professional engineering is to earn a bachelor's degree. The curriculum includes math, science, humanities and other courses that are applicable to many careers.

Some engineers earn a master's or doctorate degree to specialize in a particular area. They can expand your options for a career and increase your job prospects.

You can also choose to take a course that is specific to your industry, like oil and gas or mining. These courses will teach you to assess underground resources, such as metals and petroleum.

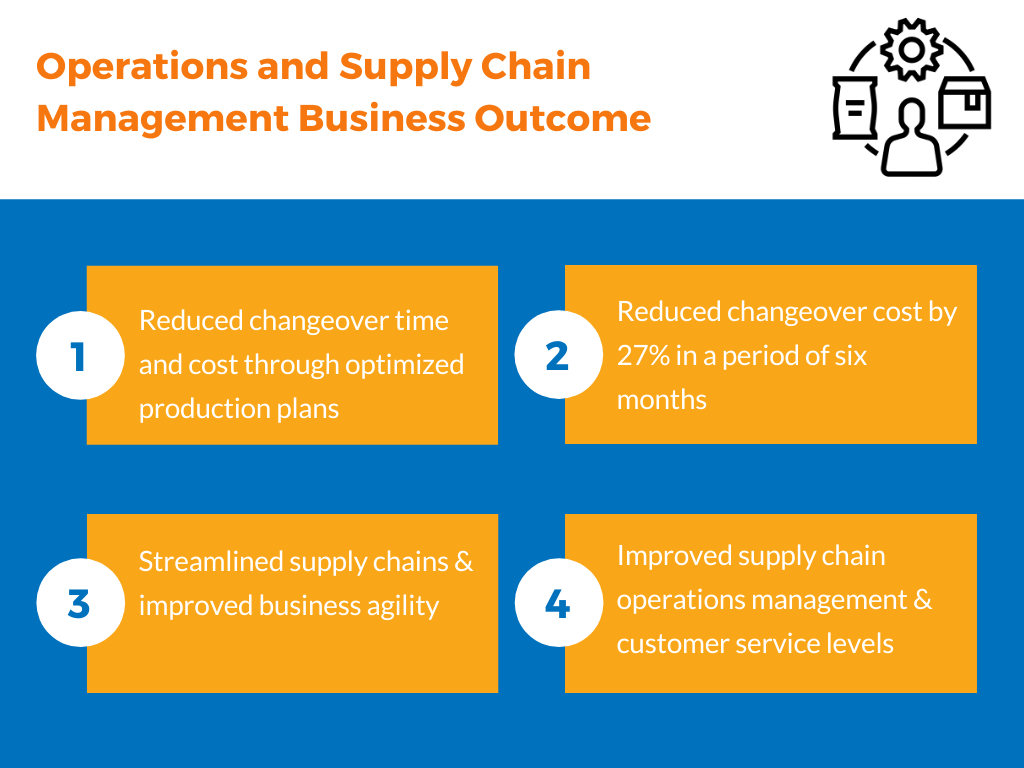

Manufacturing is the process that transforms raw materials into finished goods for sale in markets or stores. Learn the basics of production as well as how to plan, and then execute production lines.

As an engineer, you'll need to be able to work under pressure and handle a variety of responsibilities. You will need to manage your schedule and prioritize tasks to ensure that you complete all of them within the timeframe.

You should choose a school that offers an accredited engineering degree program. This designation signifies that ABET, the US-based organization that accredits programs for engineering education, has approved the school's program.

You'll have to go to college full-time and for four semesters, earning a total of at least 60 credits. You'll also need to pass an examination and complete a work-experience internship in the engineering field you choose.

The average salary for a study engineering is $94,463 annually. An entry-level salary is about $30,000, and a senior researcher engineer's salary is about $123,325 per year.

You'll be tasked with identifying technologies that will help businesses produce products more efficiently or at a lower cost, as well as developing designs and testing prototyping for ease-of-use, longevity, and functionality. It may also include collaborating with product development and marketing to refine existing products or developing new ones.

During your work as a study engineer, you'll need to spend a significant amount of time in the lab and on the job. You will need to be able perform complex data analyses and have a solid grasp of the science behind engineering projects.

You must be passionate about science and enjoy solving problems. You'll also need to have a background in physics, math and chemistry.

The best way for you to prepare to enter a career in Engineering is to attend an accredited program. You can then take the FE Exam after you graduate. Next, you need to acquire some engineering work before taking the PE examination and becoming licensed.

FAQ

What are the responsibilities for a manufacturing manager

A manufacturing manager must ensure that all manufacturing processes are efficient and effective. They should also be aware and responsive to any company problems.

They should also learn how to communicate effectively with other departments, including sales and marketing.

They should be informed about industry trends and be able make use of this information to improve their productivity and efficiency.

What does it take to run a logistics business?

It takes a lot of skills and knowledge to run a successful logistics business. Good communication skills are essential to effectively communicate with your suppliers and clients. You should be able analyse data and draw inferences. You need to be able work under pressure and manage stressful situations. You need to be innovative and creative to come up with new ways to increase efficiency. To motivate and guide your team towards reaching organizational goals, you must have strong leadership skills.

It is also important to be efficient and well organized in order meet deadlines.

What is meant by manufacturing industries?

Manufacturing Industries are businesses that produce products for sale. These products are sold to consumers. These companies use various processes such as production, distribution, retailing, management, etc., to fulfill this purpose. They create goods from raw materials, using machines and various other equipment. This includes all types manufactured goods such as clothing, building materials, furniture, electronics, tools and machinery.

What does "warehouse" mean?

Warehouses and storage facilities are where goods are kept before being sold. It can be either an indoor or outdoor space. In some cases, it may be a combination of both.

Why is logistics important in manufacturing

Logistics are essential to any business. Logistics can help you achieve amazing results by helping to manage product flow from raw materials to finished products.

Logistics also play a major role in reducing costs and increasing efficiency.

What is the job of a production plan?

Production planners make sure that every aspect of the project is delivered on-time, within budget, and within schedule. They also ensure the quality of the product and service meets the client's requirements.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- (2:04) MTO is a production technique wherein products are customized according to customer specifications, and production only starts after an order is received. (oracle.com)

- It's estimated that 10.8% of the U.S. GDP in 2020 was contributed to manufacturing. (investopedia.com)

External Links

How To

How to Use 5S to Increase Productivity in Manufacturing

5S stands for "Sort", 'Set In Order", 'Standardize', & Separate>. Toyota Motor Corporation created the 5S methodology in 1954. It helps companies achieve higher levels of efficiency by improving their work environment.

This method aims to standardize production processes so that they are repeatable, measurable and predictable. It means tasks like cleaning, sorting or packing, labeling, and storing are done every day. Through these actions, workers can perform their jobs more efficiently because they know what to expect from them.

Implementing 5S involves five steps: Sort, Set in Order, Standardize Separate, Store, and Each step requires a different action, which increases efficiency. For example, when you sort things, you make them easy to find later. When you set items in an order, you put items together. After you have divided your inventory into groups you can store them in easy-to-reach containers. Make sure everything is correctly labeled when you label your containers.

Employees must be able to critically examine their work practices. Employees need to understand the reasons they do certain jobs and determine if there is a better way. They will need to develop new skills and techniques in order for the 5S system to be implemented.

The 5S Method not only improves efficiency, but it also helps employees to be more productive and happier. Once they start to notice improvements, they are motivated to keep working towards their goal of increasing efficiency.