Are you searching for a job as an industrial engineer? Read on to discover what types of jobs are available. This article will talk about the different types of jobs, their average salary and the educational requirements. We will also discuss the skills required and where you can find them. You can then apply for the job that appeals to you the most! Good luck! Applying for an industrial engineering position is a good idea. Make sure to carefully review the job description before you submit your application.

Job description

Industrial engineers aren't for everyone. The job requires the application of engineering principles and technology to improve production layouts and processes in companies. This type of engineer is responsible for developing tools and analytics that help companies monitor their costs and schedules. He or she also reviews production data to determine areas for improvement and compiles equipment and material lists, as well as cost analyses, production cost estimations, and purchase orders before implementing new projects.

A degree in mechanical engineering is necessary to be employed as an industrial engineer. This job requires an in-depth knowledge of engineering principles. Industrial engineers often need to be able to combine their technical knowledge with a deeper understanding of people's capabilities and needs. Industrial engineers need to be organized and have strong analytical skills. They also need to be good communicators. They are responsible to improve the production processes of businesses and manage warehouses and factories.

Salary range

The starting salary for industrial engineers is around $85,000, but it varies depending on the experience. The starting salary for industrial engineers is $85,000. However, the maximum amount of compensation can be up to $100,000. Below is a table that outlines the range of salaries for industrial engineers based on experience. For example, an Entry Level Engineer can expect to make about $86,000 per year in Ventura, California. For experienced Industrial Engineers, the range of salary is $85,000 to $100,000. It is possible to get hired as Project Engineer. This usually requires a four year degree.

The average salary for Industrial Engineers varies depending upon where they are located, their industry and the years of experience. In New York, industrial engineers can expect to earn from $60,700 to $140,000 annually. Although the trend towards higher salaries is not easy to track, they have increased by more 40 percent over 10 years. Expectations are that this trend will continue. To learn more about salary ranges in your area, use Monster's Salary Tool.

Education required

While licensing may not be required for industrial engineers it is a requirement for government contracts. For entry level positions, industrial engineers do not require licensing. For professional licensure, however, they will need to have relevant experience and a degree from an institution that is accredited. Industrial engineers can be found working in offices, factories, and labs. Many industrial engineers find employment in aerospace product manufacturing, architectural and engineering services, navigational equipment, and medical and control instruments manufacturing.

Many industrial engineers opt to do internships while in college. This can give them valuable experience. Although industrial engineering jobs at entry level do not typically require professional experience, obtaining additional experience through other engineering roles can give you an edge over your competition. Internships can be very valuable if your goal is to work in government or another organisation. An industrial engineer may need to be cleared for security clearance, in addition to interning.

Places

Industrial engineering jobs are available in a variety of settings and can be highly rewarding. These positions are typically entry-level and involve the completion of calculations, installation and testing of devices, as well as documentation. These professionals may also contribute to the development of budgets or tracking metrics. A lot of standing is required for industrial engineers. Industrial engineers must be able to effectively communicate. Sometimes they work with a more senior engineer.

Industrial engineers are employed by companies to develop efficient production processes that consume the minimum amount of energy and other resources. Their main goal is to find ways to streamline the production process, while ensuring maximum labor efficiency. Industrial engineers work in offices, factories and other settings to improve the operational efficiency of companies. An undergraduate degree in industrial engineer or another related field is necessary to hold an entry-level position in industrial engineers. According to the Bureau of Labor Statistics in 2021, industrial engineers will earn a median salary of $95,300.

FAQ

How can we increase manufacturing efficiency?

First, determine which factors have the greatest impact on production time. The next step is to identify the most important factors that affect production time. If you aren't sure where to begin, think about the factors that have the greatest impact on production time. Once you have identified the factors, then try to find solutions.

What do we need to know about Manufacturing Processes in order to learn more about Logistics?

No. No. But, being familiar with manufacturing processes will give you a better understanding about how logistics works.

What are the essential elements of running a logistics firm?

It takes a lot of skills and knowledge to run a successful logistics business. Good communication skills are essential to effectively communicate with your suppliers and clients. You must be able analyze data and draw out conclusions. You must be able to work well under pressure and handle stressful situations. To increase efficiency and creativity, you need to be creative. You will need strong leadership skills to motivate and direct your team members towards achieving their organizational goals.

You must be organized to meet tight deadlines.

What skills should a production planner have?

To become a successful production planner, you need to be organized, flexible, and able to multitask. Also, you must be able and willing to communicate with clients and coworkers.

What is the role of a production manager?

Production planners ensure all aspects of the project are delivered within time and budget. They also ensure that the product/service meets the client’s needs.

Statistics

- According to a Statista study, U.S. businesses spent $1.63 trillion on logistics in 2019, moving goods from origin to end user through various supply chain network segments. (netsuite.com)

- In 2021, an estimated 12.1 million Americans work in the manufacturing sector.6 (investopedia.com)

- You can multiply the result by 100 to get the total percent of monthly overhead. (investopedia.com)

- In the United States, for example, manufacturing makes up 15% of the economic output. (twi-global.com)

- Job #1 is delivering the ordered product according to specifications: color, size, brand, and quantity. (netsuite.com)

External Links

How To

How to use Lean Manufacturing in the production of goods

Lean manufacturing (or lean manufacturing) is a style of management that aims to increase efficiency, reduce waste and improve performance through continuous improvement. It was developed in Japan between 1970 and 1980 by Taiichi Ohno. TPS founder Kanji Tyoda gave him the Toyota Production System, or TPS award. Michael L. Watkins published the first book on lean manufacturing in 1990.

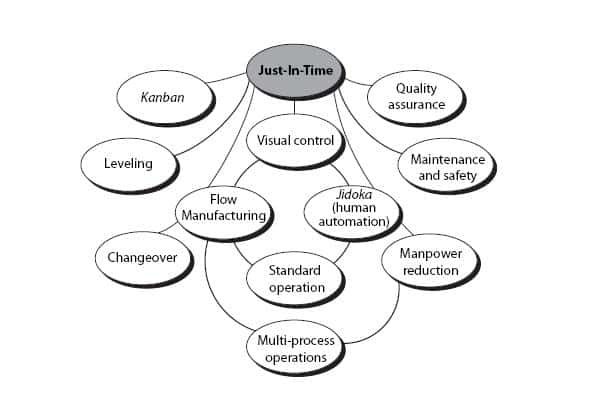

Lean manufacturing is often described as a set if principles that help improve the quality and speed of products and services. It emphasizes eliminating waste and defects throughout the value stream. Lean manufacturing can be described as just-in–time (JIT), total productive maintenance, zero defect (TPM), or even 5S. Lean manufacturing focuses on eliminating non-value-added activities such as rework, inspection, and waiting.

Lean manufacturing can help companies improve their product quality and reduce costs. Additionally, it helps them achieve their goals more quickly and reduces employee turnover. Lean manufacturing can be used to manage all aspects of the value chain. Customers, suppliers, distributors, retailers and employees are all included. Lean manufacturing practices are widespread in many industries. Toyota's philosophy is a great example of this. It has helped to create success in automobiles as well electronics, appliances and healthcare.

Lean manufacturing is based on five principles:

-

Define Value - Identify the value your business adds to society and what makes you different from competitors.

-

Reduce Waste - Eliminate any activity that doesn't add value along the supply chain.

-

Create Flow - Ensure work moves smoothly through the process without interruption.

-

Standardize and simplify – Make processes as repeatable and consistent as possible.

-

Building Relationships – Establish personal relationships with both external and internal stakeholders.

Lean manufacturing isn’t new, but it has seen a renewed interest since 2008 due to the global financial crisis. Many businesses are now using lean manufacturing to improve their competitiveness. Some economists even believe that lean manufacturing can be a key factor in economic recovery.

Lean manufacturing, which has many benefits, is now a standard practice in the automotive industry. These include improved customer satisfaction, reduced inventory levels, lower operating costs, increased productivity, and better overall safety.

Lean manufacturing can be applied to almost every aspect of an organization. However, it is particularly useful when applied to the production side of an organization because it ensures that all steps in the value chain are efficient and effective.

There are three types of lean manufacturing.

-

Just-in-Time Manufacturing: Also known as "pull systems", this type of lean manufacturing uses just-in-time manufacturing (JIT). JIT refers to a system in which components are assembled at the point of use instead of being produced ahead of time. This approach is designed to reduce lead times and increase the availability of components. It also reduces inventory.

-

Zero Defects Manufacturing, (ZDM): ZDM is focused on ensuring that no defective products leave the manufacturing facility. Repairing a part that is damaged during assembly should be done, not scrapping. This applies to finished goods that may require minor repairs before shipment.

-

Continuous Improvement (CI), also known as Continuous Improvement, aims at improving the efficiency of operations through continuous identification and improvement to minimize or eliminate waste. Continuous improvement involves continuous improvement of processes and people as well as tools.